What is a Rotary Valve?

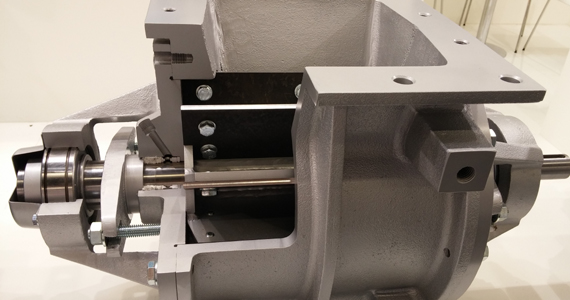

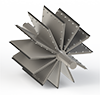

It is a compact mechanical device for continuously discharging bulk powders or granules under gravity flow. By definition it is the simplest of machines having only one moving part (ignoring the drive); a multi-vane rotor revolving in close contact in the housing and where the housing has an inlet at the top, and an outlet at the bottom.

Despite its simplicity it offers several functional uses:-

* Control product flow rate to the required rate (fixed or variable)

* Maintain a gas pressure differential between the inlet & outlet (AIRLOCK)

* Act as an explosion barrier

* Act as a Flame Barrier

* Act as a process isolator / barrier

As well as satisfying any one or any combination of these needs, the valve also has to overcome

any adverse characteriStics of the product being handled. To complicate matters further product

characteriStics can be altered by the duty conditions which are not always stable.

Notwithstanding the above some 60%+ of applications can be readily satisfied from standard

components and, if necessary, the inclusion of common additional features. The remainder tend to

require specialist input in order to ensure satisfactory performance and service life.

In all cases, technically competent suppliers will examine the duty carefully to ensure that the right

unit is offered, and to be sure that any special considerations are identified and provision made.

EXPLANATION OF A ROTARY AIRLOCK VALVE

Rotary AIRLOCKs are referred to by many different names. Some are appropriate, and some are not. There are three appropriate names which are universally accepted when referring to this product.

Technically, they all refer to a similar device in terms of design and appearance. These are:

1. Rotary Feeder

2. Rotary Valve

3. Rotary AIRLOCK

Most suppliers and users are familiar with all these terms. We will focus on the term rotary AIRLOCK for the purpose of this discussion. To further identify the name rotary AIRLOCK, we will define the two separate terms.

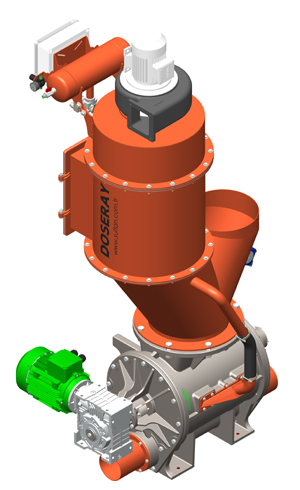

Rotary Valve , AIRLOCKS Function

Our Rotary Valves, designed according to a criteria of maximum applicative universality, are suitable for controlled feeding or discharging of products in powder or

granular form, from silos, hoppers, pneumatic conveying systems, bag filters or cyclones.

AIRLOCK, ROTARY VALVE - ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

- OPEN AND CLOSED END ROTORS

RELIEVED ROTOR TIPS

REDUCE CAPACITY ROTORS

TEFLON COATED AND NICKEL PLATED ROTORS

ROUND AND SQUARE FLANGE

DIRECT-DRIVE AND CUSTOM DRIVE PACKAGES

HIGH TEMPERATURE MODIFICATIONS

SPECIAL PAINT

FLEX TIPS

ABRASION RESISTANT TIPS

CHROME PLATED HOUSINGS

CAVITY AND SHAFT AIR PURGE - Every pneumatic process is unique, so

DOSERAY customizes every solution to meet your

needs. Pneumatic conveying systems and components are what

we know, no

matter how large or small your line. Tell us what you intend to accomplish and well make sure the pieces fit.Dependable, versatile systems. Solutions that fit. Its the foundation of our business.

Rotary Valve PDF brochure

Why Choose a DOSERAY Rotary AIRLOCK?

Air Filtration provides a complete line of rotary valve - AIRLOCKs

suitable for AIR LOCK applications ranging from gravity discharge

of filters, rotary valves, cyclone dust collectors, and rotary

valve - AIRLOCK storage devices to precision feeders for dilute

phase and continuous dense phase pneumatic conveying systems.

Rotary Valve / AIRLOCK Feeders are used in pneumatic conveying

systems, dust control equipment, and as volumetric feed-controls

to maintain an even flow of material through processing systems.

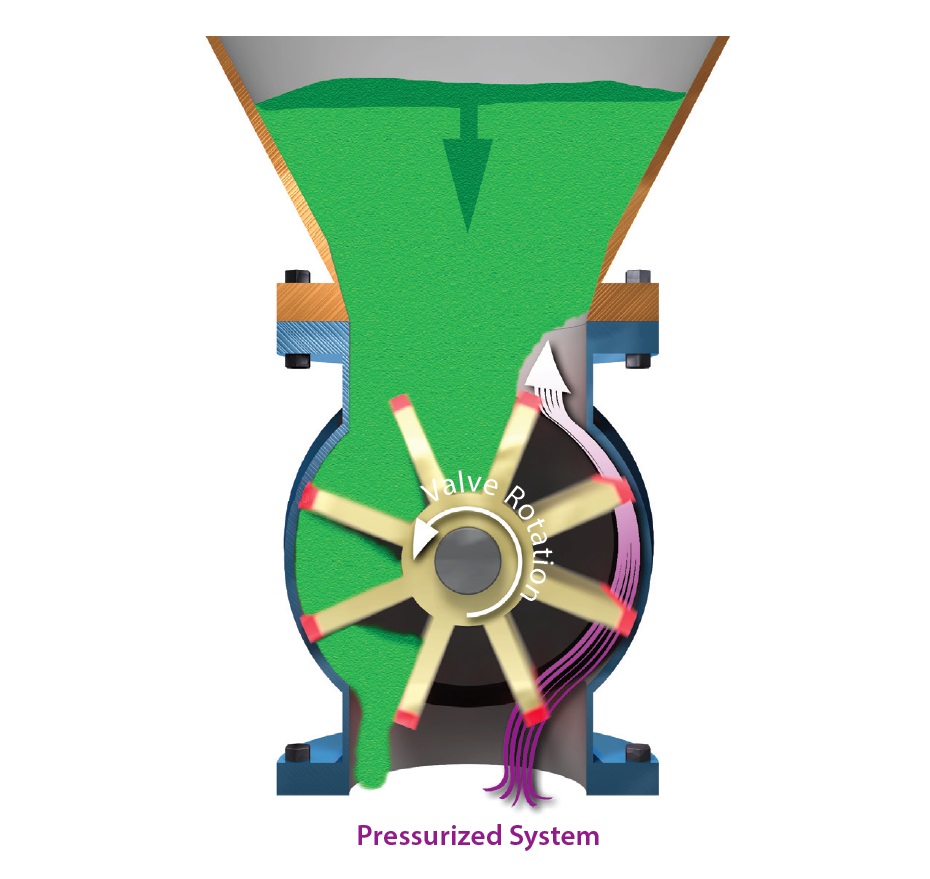

The basic use of the rotary valve, AIRLOCK feeder is as an AIRLOCK

transition point, sealing pressurized systems against loss of air

or gas while maintaining a flow of material between components

with different pressure. Rotary Valve, AIRLOCK Valves are also

widely used as volumetric feeders for metering materials at

precise flow rates from bins, hoppers, or silos onto conveying or

processing systems.

Blow Through Rotary Valves

BLOW-THROUGH ROTARY AIRLOCK VALVE - DOSING OF POWDER FOR

FEEDING PNEUMATIC CONVEY SYSTEMS

Cast iron, 304, 316L

stainless construction

These rotary AIRLOCK valves are designed for

extraction applications under devices (supported or not), gravity

flow or feeding in pneumatic conveying (depression or pressure).

The rotary AIRLOCK valves are designed for feeding and

controlled discharge of powdered or granular in silos, hoppers,

pneumatic conveying systems, bag filters, cyclones in powder

handling processes.otary valve is of no use by itself. Rotary valve,

AIRLOCKs are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, AIRLOCK Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

CAUSES OF WEAR AND ABRASION TO ROTARY AIRLOCK VALVES

Among the leading causes of rotary AIRLOCK valve

failures is wear to either rotor, or housing, or both.

Wear of these components occurs during use.

Since a rotary AIRLOCK valve is primarily a material

handling device, it is subject to erosion and abrasion

created by the material being processed. The

proper selection of one rotary AIRLOCK valve for an

application depends, to a large extent, on the nature

and characteriStics of the material being processed;

and how the material is being processed.

From an overview, rotary AIRLOCK valves are used in

material processing applications ranging from flour

to

rocks, plaStics to potatoes, dust to detergents,

peanut hulls to cotton seed, carrot tops to salt, coal

to rice, wood chips to aluminum shavings, and many,

many

more materials too numerous to mention.

Some of these materials are abrasive, some are not.

Those that are abrasive are not necessarily equally

abrasive by comparison. There are, of course, other

considerations for each material other than abrasion,

but our focus for this discussion is going to be on

the abrasive characteriStics and their effect on the

AIRLOCK components Wear, due

to abrasion, from a material being

processed through a rotary AIRLOCK valve can be

divided into two types:

1. Surface drag abrasion

2. Pneumatic assisted abrasion

- Lebels: rotary valve, rotary AIRLOCK, AIRLOCK valve, rotary feeder, blow through rotary valve, flow through AIRLOCK, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary AIR LOCK valve, rotary valve producer , rotary valve price, rotary valve draw