How the AIRLOCK Rotary Valve Star Feeder Valve is Used?

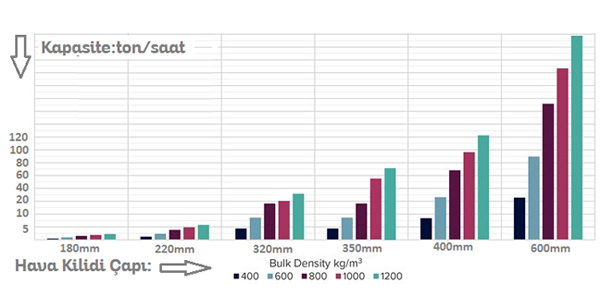

Granules conveying with rotary valveThe rotary valve system is suitable for high and low capacity installations. The rotary valve feeds the material into the positive air stream generated by the Multiair blower. After having been carried through the smooth pipe system, the cyclone separates the material from the air stream at the discharge point. These systems can be built quickly using Kongskildes unique standard modular components and can be installed virtually anywhere.

offset type pellet-granul Rotary Valve

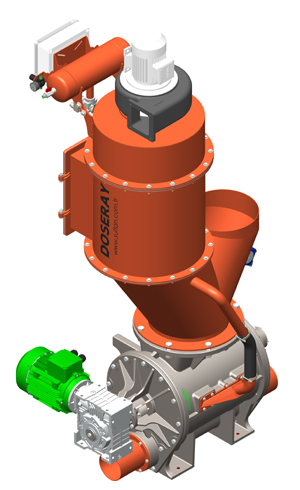

The main feature of a Rotary Airlock is to regulate the flow of material from one chamber to another while maintaining a good airlock condition. The material or product being handled is usually dry free flowing powder, dust or granules.

The granule type of product, especially if it is a plaStic type, polythene or nylon etc., does not shear easily and consequently, without considerable care the standard drop-through type of valve leads to valve seizure and also considerable shock loadings.

To minimize these problems the Offset Rotary Airlock ensures lower pocket fillage as its design means that the rotor is Still being filled in the upward cycle with the pellets falling away at the shear point. Similarly, the pelican beak distributes the product across the full width of the rotor.

airlock body. This addition substantially reduces the amount of downtime and the number of man hours required for the cleaning and maintenance of the rotor and airlock internals.

AIRLOCK, ROTARY VALVE - ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

Rotary Valve PDF brochure

Why Choose a DOSERAY Rotary AIRLOCK?

Rotary valves (also called rotary feeders and rotary airlocks)

are devices used to meter, feed, and discharge fine-grained and

powdered bulk or granular materials.

Rotary valves are

installed under silos and also hoppers in order to handle pressure

differentials, i.e., between the silo pressure when receiving the

bulk material and the pressure of downstream conveying equipment

such as tube chain conveyors, screw conveyors, trough chain

conveyors, controlled feed belt weighers, etc.

Rotary valves

are also installed under filters and cyclones in order to be able

to take bulk materials from pneumatic conveying circuits without

causing a large pressure drop in them.

They are also placed

above mixers, driers, and mills in order to volumetrically feed

bulk materials into continuous mixing and processing processes.

And they can also be used in combination with weighing devices in

order to use even more precise gravimetric feeding.

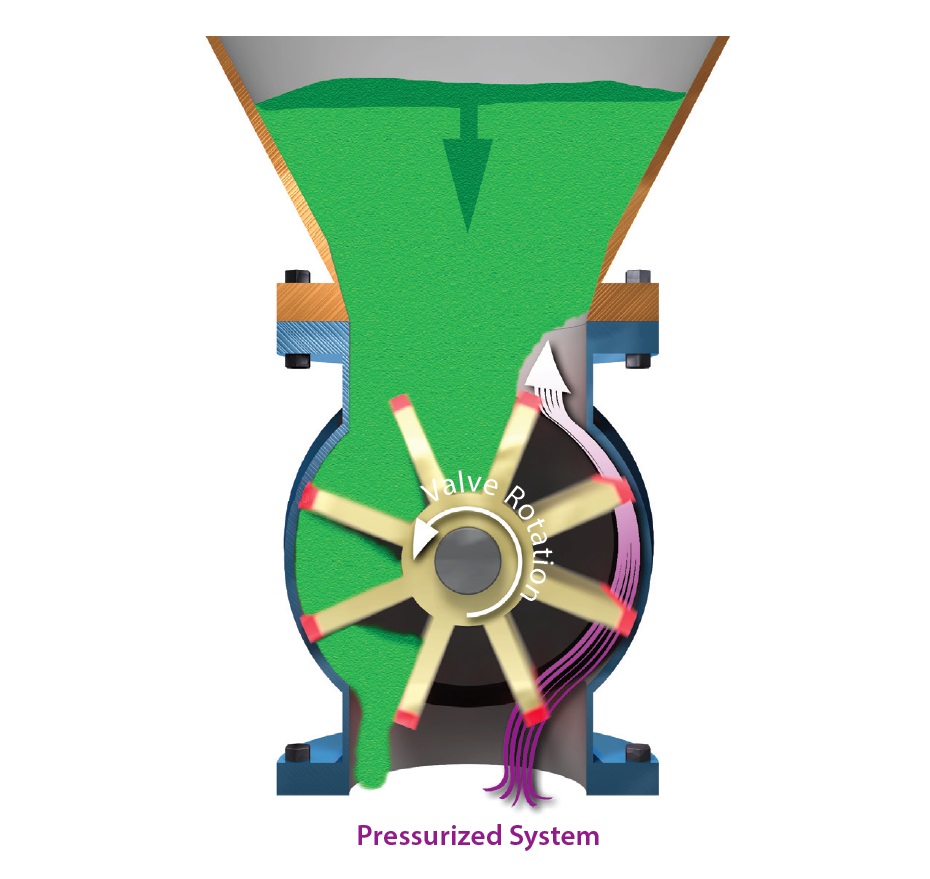

A

rotary valves operation is based on a rotor with a specific

number of rotor vanes. It rotates inside a housing with the same

contour as the vanes, i.e., a housing with an excellent fit

relative to the rotor. Each rotor pocket takes in material from

the inlet opening and discharges it through the outlet, producing

a volumetrically continuous conveyance flow. The delivery rate in

this particular case is defined by the content of the rotor

pockets and the rotors speed. The small clearance between the

housing and the rotor efficiently separates the conveyor systems

flow and counterflow directions with

specific pressure differentials.

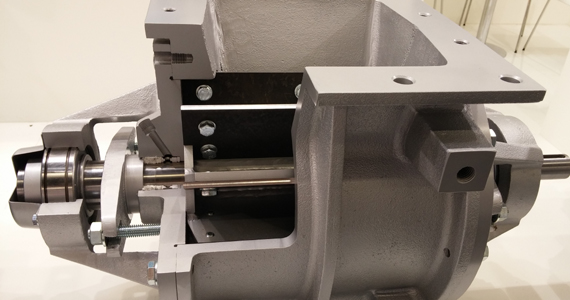

A rotary airlock is made

up of:

A housing

A rotor

A bearing

A drive mechanism

An unloading mechanism

Conveying line connections

Rotary valves can be found in a large variety of designs,

materials, and sizes.

Drop-thru rotary valves are the most

commonly used type of rotary valve. They are used as an valve

transition point for the volumetric feeding and discharging of all

kinds of bulk materials.

Self-cleaning rotary valves are

often used when dealing with caking or slightly Sticky bulk

materials. A self-cleaning rotary valve scratches the rotors

pockets empty, ensuring that the

bulk material being handled is

smoothly conveyed.

Side entry rotary valves are usually

used with coarse-grained bulk materials and with granular

materials. The offset inlet, which connects to the rotor diameter

almost tangentially, causes the bulk material to be pushed back by

the scraper, preventing it from becoming jammed between the rotary

valve and the housing. Side entry rotary valves are often used to

convey and meter granular materials in order to prevent damage to

them and ensure that grains are not destroyed.

Blow-through

rotary valves are used to convey bulk materials in pneumatic

conveying systems. The pockets move the product into a conveying

tube, where it is moved by an air stream and blown into the

conveying line.

Much like blow-through rotary valves,

rotary valves with injector valves are used to convey bulk

materials into pneumatic conveying systems. The rotary airlock

meters and conveys the product into an injector valve, where it is

moved by an air stream and blown into the conveying line.

Chemical and pharmaceutical rotary valves are used to discharge

and meter powdery foodstuffs, chemicals, and drugs.

Easy-clean rotary vlaves are used to discharge and meter powdery

foodstuffs, chemicals, and drugs. This type of rotary valve can be

thoroughly cleaned with the help of various extractors.

Knife-equipped rotary valves are used for discharging

refuse-derived fuels such as wood and plaStics. A series of

rotating and stationary knives are responsible for cutting

projecting material and preventing the rotary valve from jamming.

Dust collector rotary valves are used for discharging filter

dust from filters, separators, and cyclone collectors.

Furthermore, explosion isolation for the purpose of preventing

flame propagation in an explosion prevention system can be

implemented with a suitable rotary valves certified for use as a

safety system.

Blow ThrOUGH Rotary Valves

A rotary valve is of no use by itself. Rotary valve, AIRLOCKs are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, AIRLOCK Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

ROTARY VALVE AND PRODUCTS

Rotary AIRLOCK ( rotary valve) feeders have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include: cement, ore, sugar, minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, spray dryer, etc...

- Lebels: rotary valve, rotary AIRLOCK, AIRLOCK valve, rotary feeder, blow through rotary valve, flow through AIRLOCK, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary AIR LOCK valve, rotary valve producer , rotary valve price, rotary valve draw